Interfacing DC Motor with PIC Microcontroller using L293D

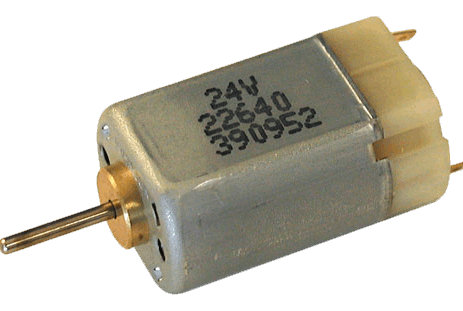

This tutorial explains " How to interface DC Motor with PIC Microcontroller ? ". DC Motor and L293D We can't drive a DC Motor (depends) directly with a Microcontroller, as DC Motors requires high current and high voltage than a Microcontroller can handle. Microcontrollers usually operates at +5 or +3.3V supply and it I/O pin can provide only up to 25mA current. Commonly used DC Motors requires 12V supply and 300mA current, moreover interfacing DC Motors directly with Microcontrollers may affect...