Smart tag to Print Electronics on Plastic

Technology is exponentially advancing day by day. Now a Norway based ThinFilm Electronics announced that they are planning to make an electronic device on a piece of plastic. Researchers at PARC and ThinFilm Electronics had developed the technology to print electronics circuits and devices on plastic by using a printer similar to one attached to our computer.

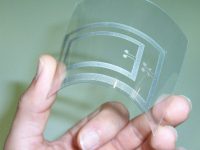

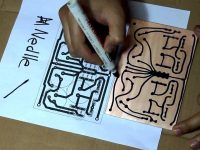

This is done by using organic ferroelectric polymer ink. The exact details are not published, but by examining the picture we can understand that it looks like a horizontal rolled-out-flat computer circuit. Instead of using multiple layers of semiconductors for making a transistor, they users different kinds of inks laid out next to each other to make memory cell or transistor. The exact size and number of components are obviously limited to the resolution of the printer.

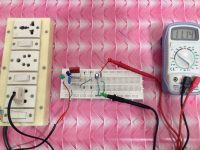

The ThinFilm Electronics company plans to create the “Smart Tag” having ThinFilm’s memory, printable transistors from the research company PARC, a display and a battery. Its first use is simple computing, temperature sensor to monitor foods or medicines such as vaccines. ThinFilm says that, this is very much useful to display the temperature record when people receive food or pharmaceuticals and it will be less expensive and accurate than placing alarm sensors in ship containers.

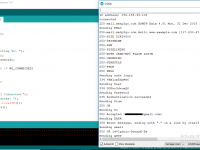

The ThinFilm’s technology has been under developing since 1900’s, it is a printable memory device which stores data in digital form as 1’s and 0’s by changing the orientation of polymer chain by applying voltages.

ThinFilm partnered with Xerox company PARC last year to combine their Ferromagnetic memory with PARC’s printed transistors and then by adding computer logic, enables the new device to read, process and to store data.

ThinFilm partnered with Xerox company PARC last year to combine their Ferromagnetic memory with PARC’s printed transistors and then by adding computer logic, enables the new device to read, process and to store data.

There are two key advantages to these printed circuits, that they are physically flexible and they are incredibly cheap to produce in vast quantities as it is using roll-to-roll printing.

The computing and storage ability are very limited but its low power and low cost, because plastic is used makes it very useful. The data can be stored many times and it is not lost during power loss. The ThinFilm says that this can be used in many applications by making partnership with companies which have developed batteries, displays and sensors for this device. The company hopes that this printable electronics replaces silicon chips. We can hope that Thinfilm’s Addressable Memory will hit the market in 2012, and as demand grows, the cost per circuit is expected to be just a few cents.

Just wait and see. . .